The reconditioning process has a large impact on a dealer’s bottom line, but they vary widely in how much time they spend getting cars ready to resell. The most efficient dealers can often recondition a car in 24 hours or less. Other dealers can take seven days or more to recondition a similar car.

It’s not surprising that the dealers who have managed to streamline the reconditioning process are the ones who are better performing in the long run.

Dealers who are more successful at maximizing their reconditioning profits generally make the connection between more time spent on reconditioning and lower profits. They’re also committed to making the necessary changes to improve their process – and their bottom line.

The following five practices have helped dealers make reconditioning faster and raise their profits accordingly:

1. Avoid a headache

If a dealer feels pressured to fill gaps in their used car inventory, they may be tempted to focus more on quantity than on quality.

Dealers with successful reconditioning departments look at CARFAX, AutoCheck, and other condition reports to look out for any red flags. Any vehicle that’s going to require a significant investment of time and money will be harder to make a profit on.

2. Begin with the end in mind

Dealers shouldn’t lose sight of the fact that the goal is to prepare a car and sell it for a profit. If they acquire vehicles that lack market appeal or are going to be hard to fix up or sell because of condition or appearance issues, they’re not likely to make a profit.

Trade-ins can be more complicated if they’re acquired in an effort to make a deal. However, dealers and managers should be able to work together to determine a car’s profit potential, and they should meet daily to review trade-ins and determine the best path to take.

3. Set a baseline cost for reconditioning

Delays in approval can grind the reconditioning process to a standstill. To avoid this, dealers can establish a target range for reconditioning jobs. Any work that falls at or below that level can proceed without approval.

Ultimately, a relatively low percentage of vehicles will usually require approval, and dealers can set up an efficient system of e-mails or text alerts to handle requests and approvals.

4. Make speed a priority

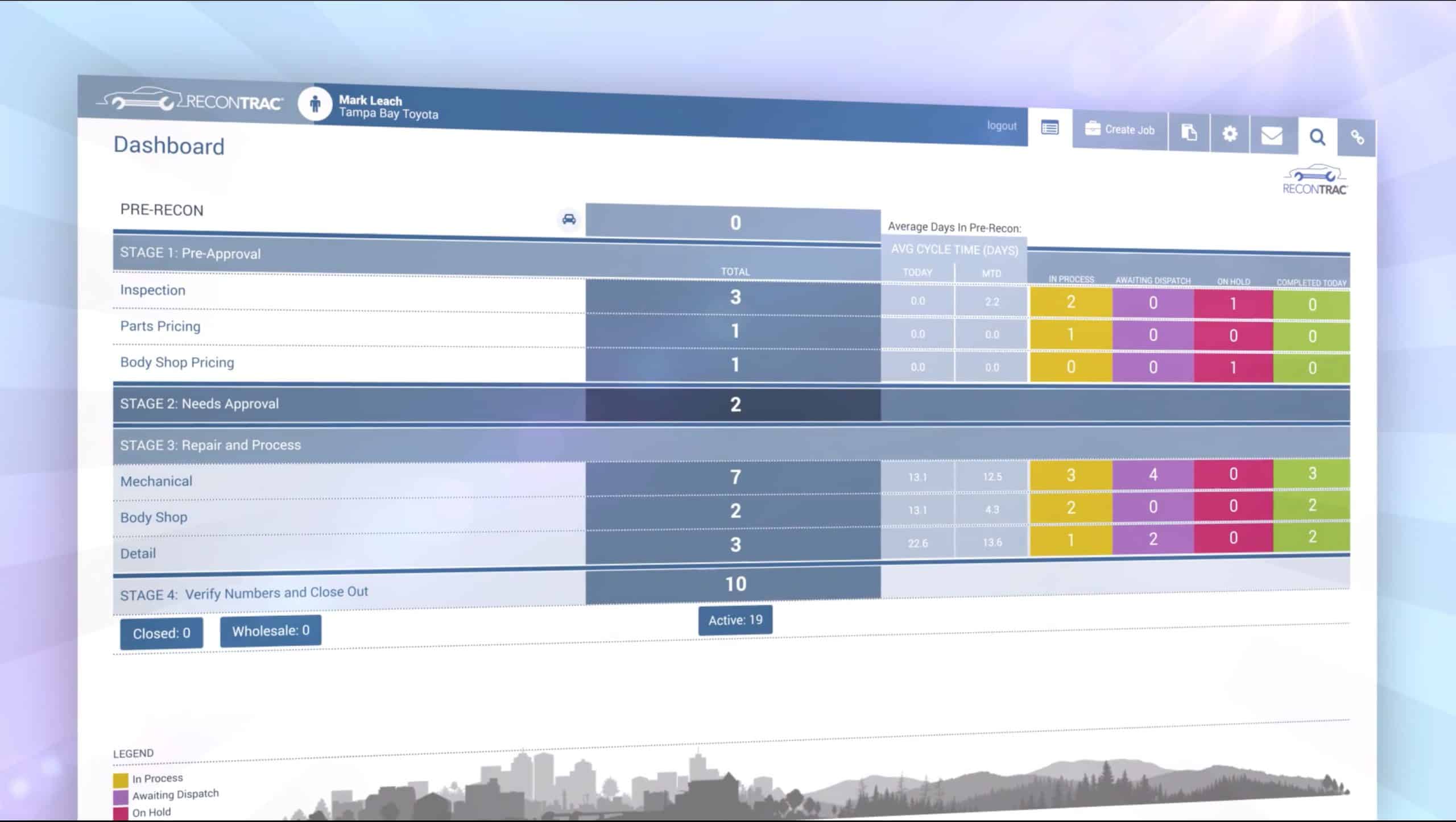

Dealers have been able to utilize ReconTRAC, a program that effectively tracks the entire reconditioning process so you can see which areas are slowing the process down and make adjustments as needed.

Reworking your departments can also help speed up the reconditioning process. One good way is to have a specific team dedicated to reconditioning, so they won’t be distracted or delayed by work from customers. Offer bonuses for meeting certain goals for speed, such as a 72-hour turnaround time.

5. Find ways to save

Many dealers have found ways to save without sacrificing the quality or safety of vehicles. Charging rates that are lower than retail for labor can help cut down on costs and increase volume. Using non-OEM (original equipment manufacturer) parts when possible can also save money. And finally, dealers can stop rubber-stamping invoices from outside vendors who do upholstery, window, and dent work. Instead, they can require these vendors to get prior approval before exceeding a certain limit.

Dealers who improve their reconditioning processes find that they’re able to turn cars over more quickly and make a greater profit on them. By taking the time to thoroughly track their process and make corrections as needed, they’ll save substantial amounts of time and money in the long run.